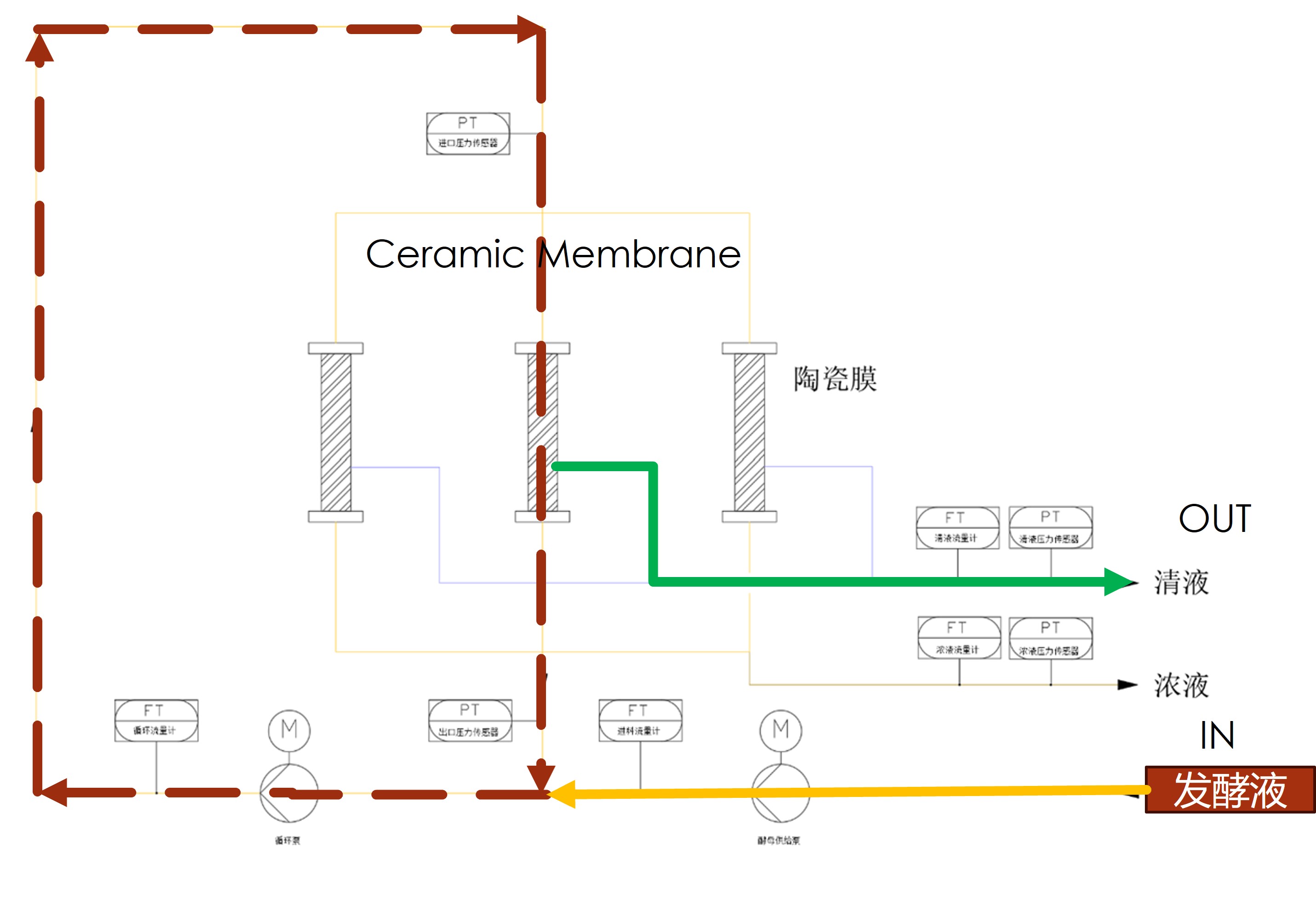

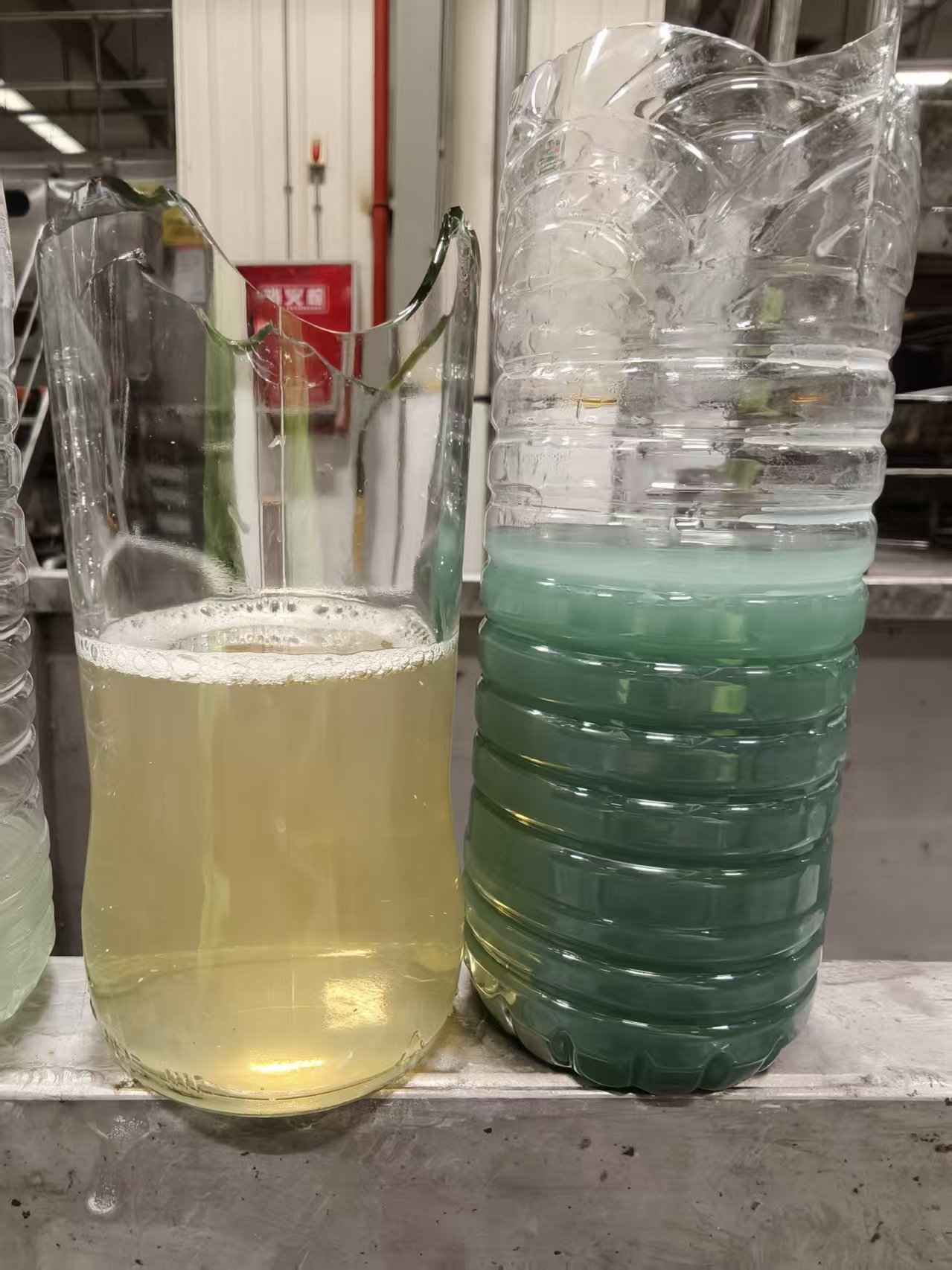

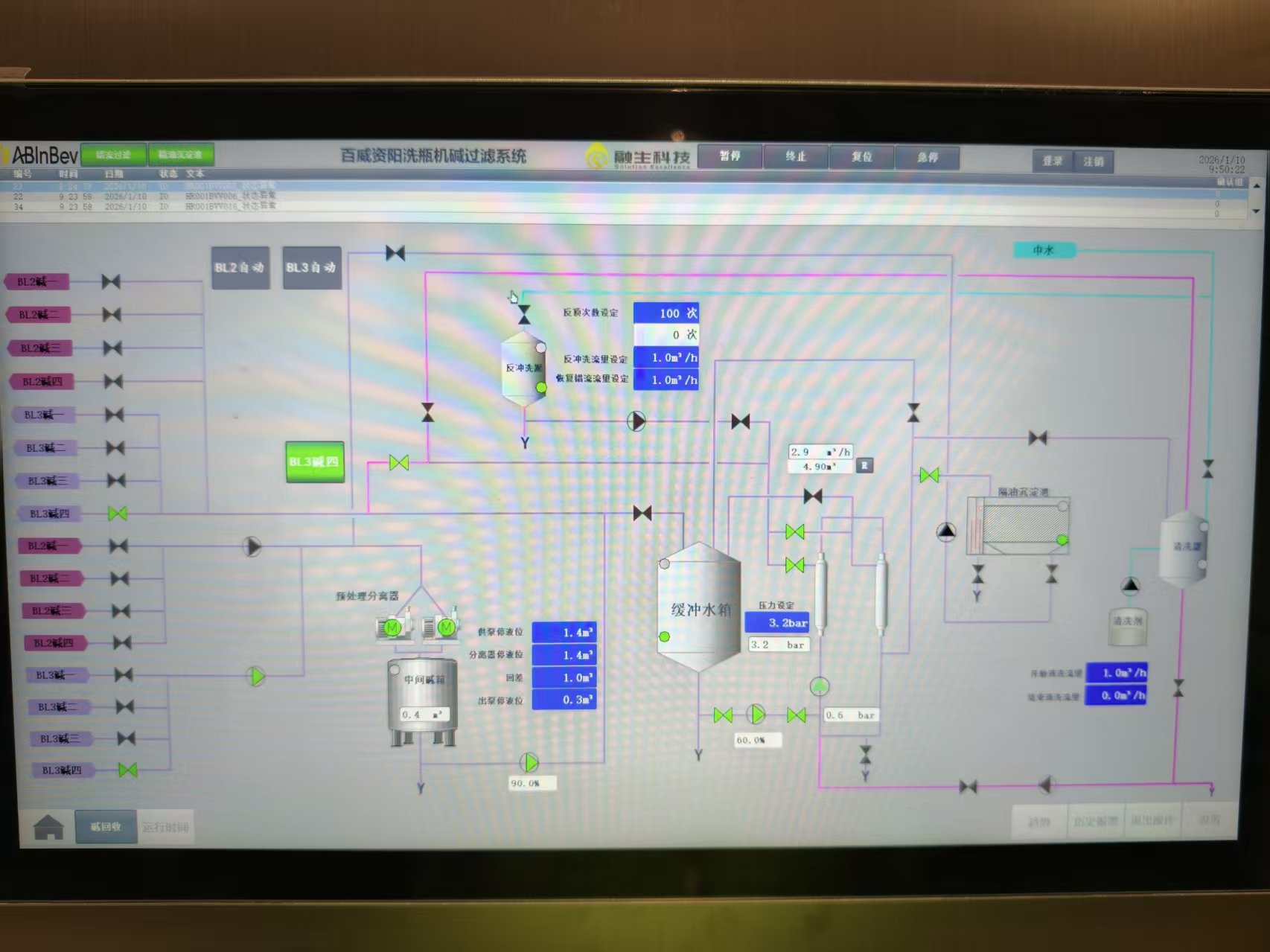

Over the past decade or so, cross-flow filtration has seen wider application with the development of various membrane technologies, especially ceramic membranes, which are increasingly used in various fields. Their stable performance, long lifespan, and superior ability to withstand harsh environments have all played a positive and beneficial role in brewing technology.

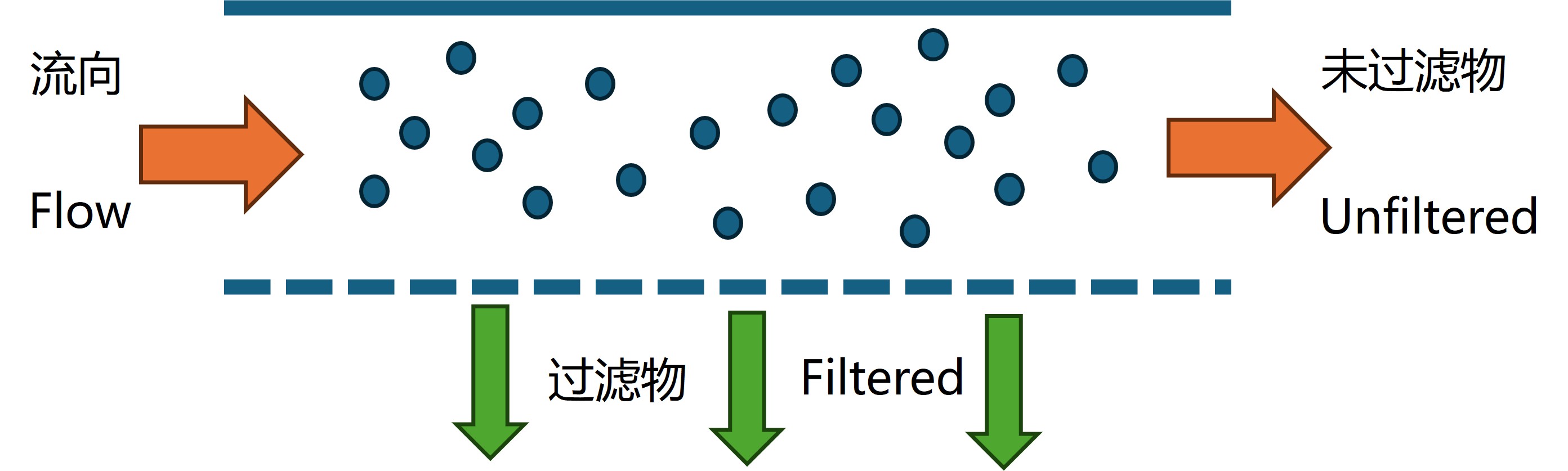

Unlike single-end filtration, cross-flow filtration operates tangentially, flushing away contaminants with the circulating flow, thus reducing membrane clogging and allowing for stable filtration over extended periods. The range of membrane options is wider, from 1 nm to several micrometers. Compared to organic membranes, ceramic membranes offer greater performance stability, can withstand higher pressures, larger temperature differences over short periods, and maintain a more consistent throughput, while also boasting a longer lifespan.